NOTE: SEE MODIFICATIONS NOTES BELOW FOR USE WITH PCM RECEIVERS !

|

MINI-FLASH KIT - Assembly Instructions |

||||

|

|

|

|

|

|

Note: All pictures that follow are "clickable". Clicking on them will show you an enlargement!

A lil' history ...

These are instructions on how to

build the Mini-Flash kit (parts)

1) One

(1) Picaxe-08M Chip (preprogrammed with MIni-Flash code)

2) Three (3) 10K ohm resistors (If PCM, need one additional 2.2K resistor)

3) One (1) Pigtail wire for Mini-Flash

4) One (1) 16 pin (8x2) Machine pin header (male)

5) Four (4) 2N2222 NPN Transistors

6) One (1) RS-232 9-pin female connector (to connect to PC com port)

7) One (1) RS-232 9-pin Hood/Cover

7) One (1) Programming Cable Pigtail (has male and female connectors)

8) One (1) Programming cable wire (4' or so)

9) 16 dual-row machine pin headers (mating connectors to 16-pin header for LEDs)

10) 3 pieces of heat shrink tubing for assembly

Building Instructions...

(Some diagrams to refer to during assembly)

NOTE: SEE MODIFICATIONS NOTES

BELOW FOR USE WITH PCM RECEIVERS !

The

Mini-Flash Kit (contents)...

The

Mini-Flash Kit (contents)...

(Programming cable wires, MIni-Flash Controller parts and RS-232 DB9 shell/case)

Picture

of the contents for the Mini-Flash controller

Picture

of the contents for the Mini-Flash controller

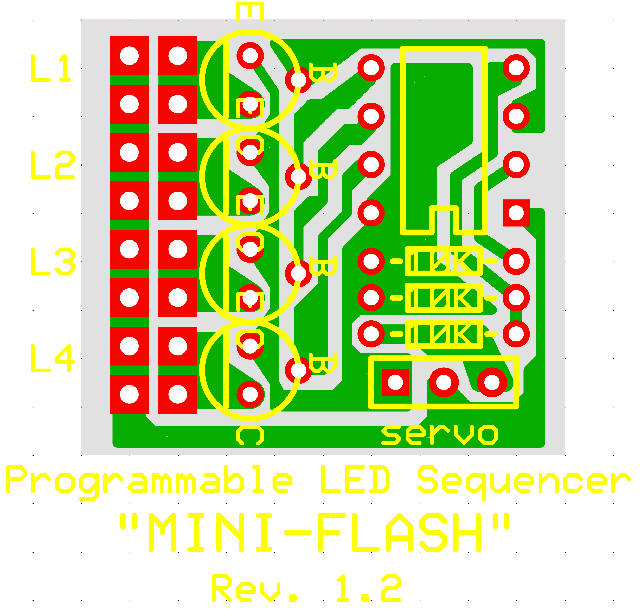

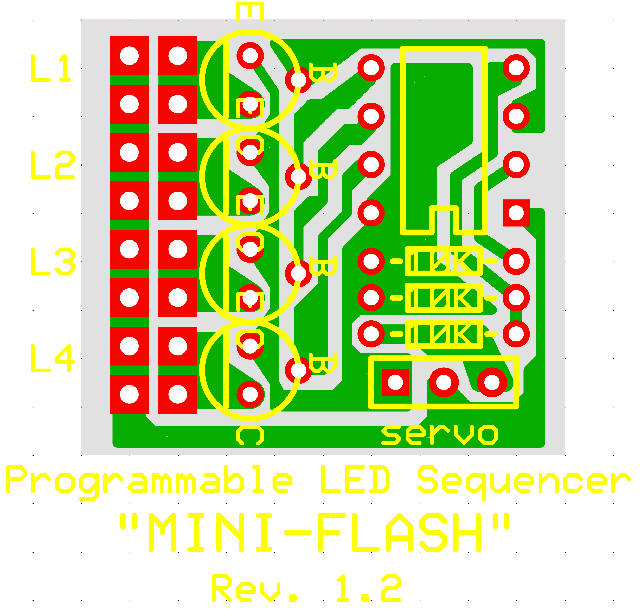

Mini-Flash controller parts laid out on table

Items pictured left to right,...

Programming/Control servo cable, three 10K resistors, PIC chip, four 2N2222

transistors, machine pin header connector, LED connectors and the printed

circuit board (PCB)

Soldering the machine pic connector onto the PCB

Soldering of the machine pin header completed (use plenty of solder).

Inserting the transistors one at a time... be sure flat side of transistor faces the header

After inserting all four (4) transistor, bend over leads and snip

Be sure transistors are pushed all the way down, so they almost touch the PCB

(see pictures below)

Solder all the transistors in place (don't use too much heat though)

You could also use a small alligator clip which you could clip on the transistor to dissipate heat. I always do and never had a transistor go bad on me when soldering. Use a low wattage iron too (i.e. 25w or so)

Now, insert all three 10K resistors and again, bend

and snip leads

NOTE: If this is to used with a PCM receiver, R3

(bottom resistor) needs to be a 2.2K, not a 10K as shown (see below).

(PCM MODIFICATION SHOWN ON LEFT)

(PCM MODIFICATION SHOWN ON LEFT)

At the same time, you can add the PIC and servo wire if you want

This is a pic of the PIC and resistors inserted, leads bent and snipped, ready for soldering.

PIC and resistors are then soldered. Again use minimal heat when soldering the PIC connections. You could also use a small alligator clip which you could clip on the PIC's leads to dissipate heat. I always do and never had a PIC go bad on me when soldering. Use a low wattage iron too (i.e. 25w or so)

The controller's servo wire has a servo plug already installed. All you need to do is strip the other ends of the three wires, tin them, then insert them into the PCB as shown below.

The tinned servo lead is inserted into the PCB and soldered.

NOTE: Pay close attention to how the leads are connected to the Mini-Flash. The ground lead (black) is connected closest to the transistors.

Note: I sometimes supply different servo leads which have black, red and white wires. On these, Red=Orange, White=Green and Black=Black.

Flip the PCB over and be sure all leads are snipped and tidy.

I usually then take a small file and file down the high connections, particularly the header pins that usually stick out a bit.

After filing, it is very important you clean the PCB completely of any residual solder flux (and metal filings!). I use a high quality deflux spray and flood the PCB until all traces of flux are gone. Using a small, stiff bristle brush helps remove the flux too.

The only thing left to do is to apply the included

heat shrink tubing/wrap. Notice how the servo wire is routed

(slight bend/loop). I usually fix the servo wire as shown here with a

little hot melt glue, just to be sure that the wire does not easily pull out.

After applying the hot melt glue, simply slide the tubing over the circuit and

slowly apply heat. Be sure the tubing shrinks just around the black part

of the header. Adjust before fully shrinking the wrap.

This is what the finished product should look like !

Now it is time to build the programming cable!

Good Job !

Programming

Cable Assembly:

Programming

Cable Assembly:

Refer to the Schematic for the Mini-Flash

Programming Cable

Locate the center of the supplied programming cable (cable with two connector) and snip both the black (ground) and green/white (servo signal/data) wires. Leave the orange/red (power) wire intact.

Locate

the other length of cable supplied with the kit (cable with no connectors).

This is the wire that will go from the RS-232 connector to the programming cable

with the connectors (shown above).

Locate

the other length of cable supplied with the kit (cable with no connectors).

This is the wire that will go from the RS-232 connector to the programming cable

with the connectors (shown above).

Strip and tin the two wire of this cable. Connect one wire (preferably darker/black wire) to both black wires on the programming cable and solder. Locate the programming cable end that has the female jack (the jack you will plug the Mini-Flash into for programming). The green/white wire leading to this connector should be connected to the other wire (red) of the cable (shown wrapped in electrical tape). The green/white wire leading to the other male connector is not connected to anything.

When you are sure you have it all put together properly, slide the piece of supplied heat shrink tubing over the other end of the cable and slide it over the connections you just made. Apply heat and shrink the tubing.

The other end of this cable is then wired to the

supplied RS-232 DB9 connector. Strip the insulation and leads of this

cable. Connect the red wire to pin#3 (Tx) and the black wire to pin#5

(ground).

NOTE: If this is to be used with a PCM receiver, you

need to add a 10K series resistor inline with the RS-232 signal, the red wire...

(see below)

(PCM MODIFICATION SHOWN ON LEFT)

After

the DB9 wiring is complete, I then tie a knot in the wire (as shown) as this is

used as a restrain such that after the DB9 case halves are assembled, the wire

can not be pulled out. You could also use the included restraining clamps

included with the DB9 case assembly... but I just find it easier to do this way.

Join the two case halves together with the two supplied screws to complete the

assembly.

After

the DB9 wiring is complete, I then tie a knot in the wire (as shown) as this is

used as a restrain such that after the DB9 case halves are assembled, the wire

can not be pulled out. You could also use the included restraining clamps

included with the DB9 case assembly... but I just find it easier to do this way.

Join the two case halves together with the two supplied screws to complete the

assembly.

YOU ARE NOW DONE!

TIME TO TEST !

Testing and Operation Instructions...

![]() CHECK

OUT THE USER'S MANUAL FOR THE MINI-FLASH !!

CHECK

OUT THE USER'S MANUAL FOR THE MINI-FLASH !!

![]()

MINI-FLASH FAQ

Q1. How do you compensate for differing forward voltages and current drawn by differing LED's?

A1. Ah.... good question....

The input voltage to LEDs is all not that important (usually 5v is fine for

all). It is the current that you push through the LED that is important, as you

do not want to drive them with too much current. You usually always need to put

a seriers resistor inline with one of the LED leads such to limit the current. I

use a neat calculator, I even have a link for it on my webpages. You really need

to know the specs on the LEDs, particularly the LEDs rated current (typical 5mm

LEDs run around 20-25 millimaps). Here's the calculator:

http://linear1.org/ckts/led.php

You simply enter the supply voltage (in the

controller's case, 5 volts), the LEDs forward voltage (this varies from LED to

LED) then enter the rated LED current (typically 20-25 millimaps). Then hit the

"find R" button and the program calculates the resistor value you need for that

LED (typically a 68 - 120 ohm resistor is required). Be careful also as there

exists some LED that already have the series resistor incorporated in the LED

(not all that common though). Once the resistor value is determined, I

usually then solder it to the end of one of the LED leads. The wires then

leading from this LED assembly is then connected directly to the controller

using a miniature machine-pin female socket (I will provide at least 8 with

every controller). Putting the series resistors on the PCB would take up

space (unless they were SMD maybe).

Q2. I have a question: So tell me how you could control different sequences with a TX like a 6102 which is a 6 channel but the 2 extras are more like landing gear, and flaps?

A2. Great question.... ( I knew I'd eventually have

write about this, as most will probably use a switch and some will have the

luxury of having a spare variable channel, like a rotating knob or lever).

Is the landing gear channel on your system controlled by a switch ? (most

likely). How about the flaps, are these a switch too or is this a rotating knob

(like I think my Futaba 9C has) ??

If the channel you have the flasher plugged into is controlled (Tx) using a

toggle switch, you will still be able to control the 4 LED channels/sequences,

but you will only have two possible servo control positions, on (*---) and off

(---*). If you were to look at the "Servo Control" pull-down in the

software, you have 16 different "servo zone" combinations you can chose. All 16

work only when you are using a variable Rx channel, such as a channel being

controlled by a knob, slider or stick. If you are only using a "switched" Rx

channel and you want to simply use the switch to turn the channel on or off, you

would set up the "servo control" such that it is "*---". What this would do is

make the selected LED channel active only when the switch is in the down

position (actually, it is as if the stick is in the position, 0->1/4

deflection). Now catch this, if you were to choose the "**--" option or the

"***-" option, this would still have the same effect. When using a toggle

switch on your Tx to control the LED flasher, the receiver will never

output the middle two zones (-**-). Therefore selecting these zones in a

channel's servo zone will do nothing.

1. TBD

2. TBD

TBD

TBD

"PICAXE is a

trademark of Revolution Education Ltd (www.picaxe.co.uk)"